COVID-19 pandemic sparked 3D printing engineering innovation

On Nov. 2, 2020, Pacific Northwest National Laboratory (PNNL) announced that in the Spring of 2020, as news spread of N95 mask and ventilator shortages in hospitals, researchers at U.S. Department of Energy (DOE) national laboratories sprang into action.

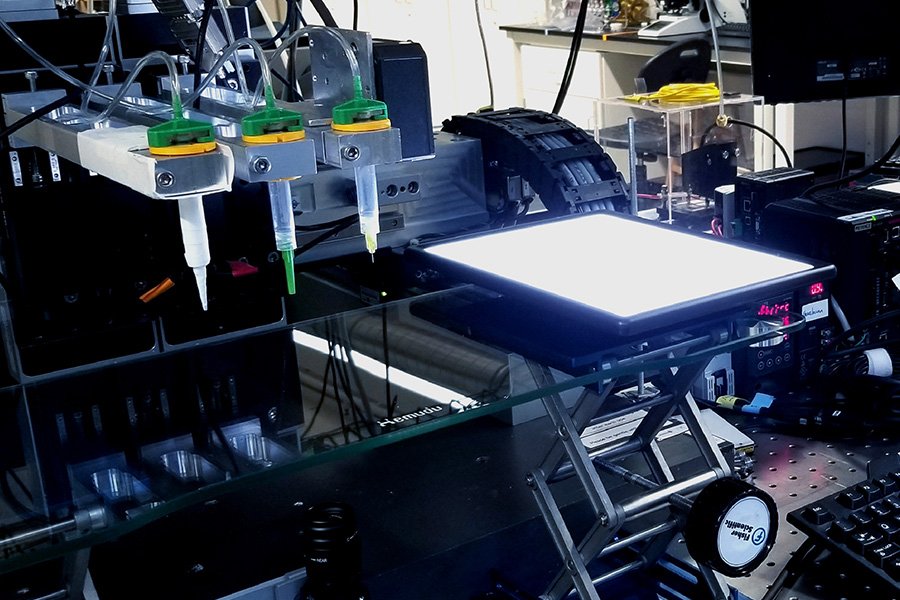

To ensure a ready supply of ventilator parts for hospitals, the PNNL engineers set to work in April, taking apart ventilator breathing circuit and figuring out how to create molds that would allow manufacturers to use new manufacturing approaches to produce parts on demand using 3D printing or additive manufacturing, to custom-design single-use ventilator ports.

With so many people relying on homemade cotton face shields to protect themselves and others, PNNL engineers puzzled out a way to customize the fit to reduce air gaps that decrease effectiveness. They designed a unique customized face covering frame design that can be used by anyone. It may be of particular interest to people at higher risk of serious, life-threatening complications from contracting COVID-19. The frame design uses the same kind of materials used in athletic mouth guards. When the material is soaked in warm water, it becomes pliable and can then be fitted to the face for a custom fit.

The design team also created a prototype for a respirator mask that uses less N95 filter material than a standard disposable mask, which would enable more masks to be made from the same volume of N95 material. To surface the best possible final design, each national laboratory in the consortium worked independently on mask designs. Once prototypes had been developed, the engineers worked together to optimize these masks for rapid manufacturing.

With the design phase of the project now complete, the masks and ventilator specifications have been made freely available as part of an initiative to accelerate technology development during the COVID-19 pandemic.

Tags:

Source: Pacific Northwest National Laboratory

Credit: